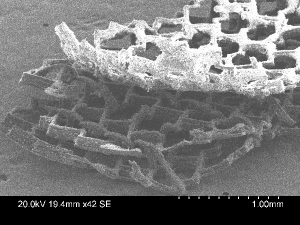

This GIF (slightly sped up) shows the honeycomb mesh of cells being compressed by contracting heart cells growing along the scaffold (Image: Boyang Zhang).

Engineers at the University of Toronto just made assembling functional heart tissue as easy as fastening your shoes. The team has created a biocompatible scaffold that allows sheets of beating heart cells to snap together just like Velcro™. “One of the main advantages is the ease of use,” says Professor Milica Radisic (ChemE, IBBME). “We can build larger tissue structures immediately before they are needed, and disassemble them just as easily. I don’t know of any other technique that gives this ability.”

Growing heart muscle cells in the lab is nothing new. The problem is that too often, these cells don’t resemble those found in the body. Real heart cells grow in an environment replete with protein scaffolds and support cells that help shape them into long, lean beating machines. In contrast, lab-grown cells often lack these supports, and tend to be amorphous and weak. Radisic and her team focus on engineering artificial environments that more closely imitate what cells see in the body, resulting in tougher, more robust cells.

This photomicrograph shows three sheets of the scaffold on top of each other; the hook and loop mechanism can be seen in the middle layer (Credit: Radisic Lab).

Two years ago, Radisic and her team invented the Biowire, in which heart cells grew around a silk suture, imitating the way real muscle fibres grow in the heart. “If you think of single fibre as a 1D structure, then the next step is to create a 2D structure and then assemble those into a 3D structure,” says Boyang Zhang a PhD. http://news.engineering.utoronto.ca/tissue-velcro/

Recent Comments