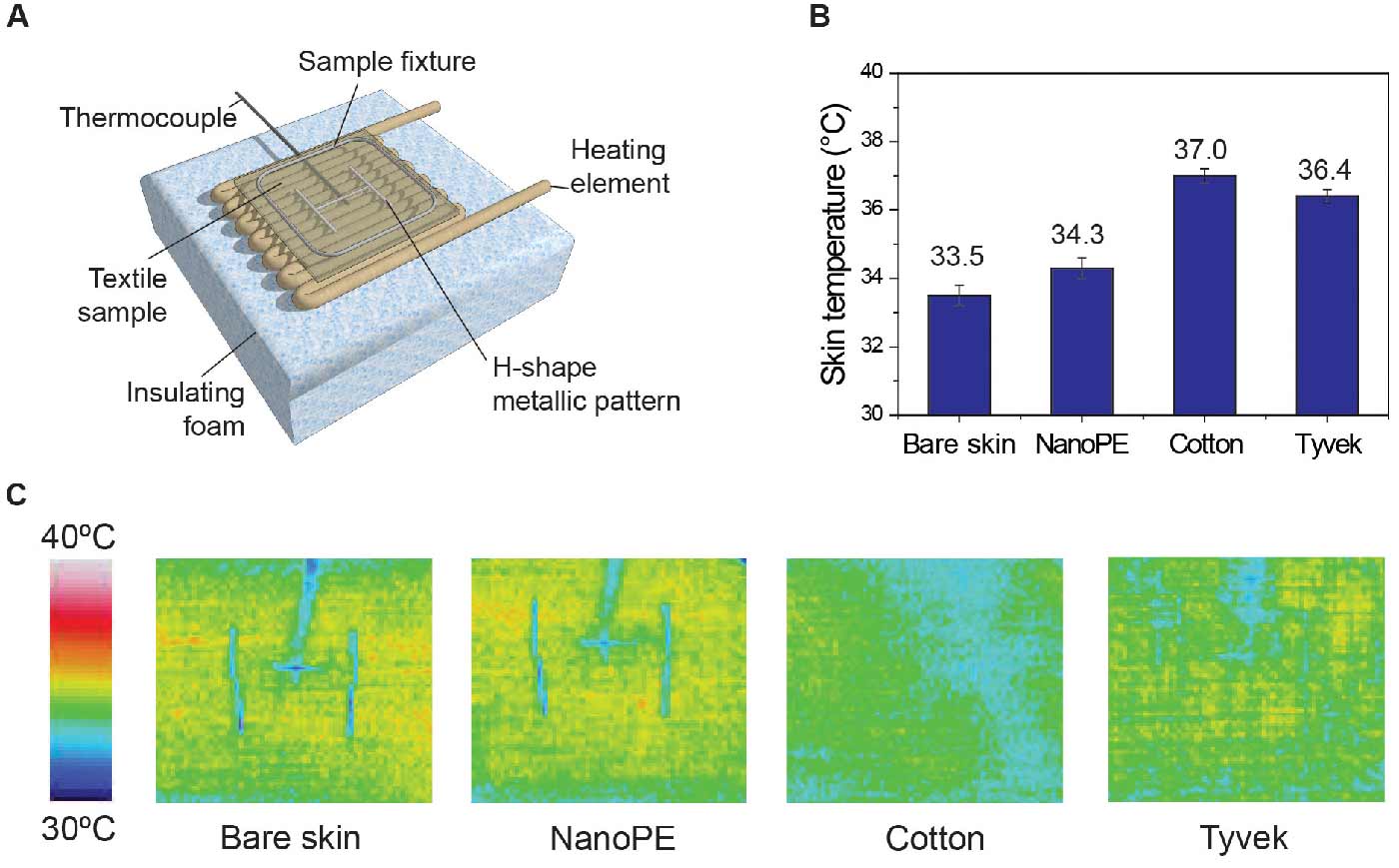

Thermal measurement of nanopolyethylene (nanoPE) and various textile samples. (A) experimental setup of textile thermal measurement. The heating element that generates constant heating power is used to simulate human skin, and the “skin temperature” is measured with the thermocouple. Lower skin temperature means a better cooling effect. (B) Thermal measurement of bare skin, nanoPE, cotton, and Tyvek. NanoPE has a much better cooling effect than that of cotton and Tyvek because of its infrared (IR)-transparency. (C) Thermal imaging of bare skin and the three samples. Only nanoPE can reveal the H-shape metallic pattern because of its IR-transparency. Photo by Stanford University.

Stanford University researchers, with the aid of the Comet supercomputer at the San Diego Supercomputer at UCSD, have engineered a low-cost plastic material that could become the basis for clothing that cools the wearer, reducing the need for energy-consuming air conditioning. This new family of fabrics could become the basis for garments that keep people cool in hot climates without air conditioning. The new material works by allowing the body to discharge heat in two ways that would make the wearer feel nearly 4F cooler than if they wore cotton clothing.

The material cools by letting perspiration evaporate through the material, something ordinary fabrics already do. But the Stanford material provides a second, revolutionary cooling mechanism: allowing heat that the body emits as infrared radiation to pass through the plastic textile. “40 to 60 percent of our body heat is dissipated as infrared radiation when we are sitting in an office,” said Prof. Shanhui Fan. “But until now there has been little or no research on designing the thermal radiation characteristics of textiles.”

The research blended computer simulations, nanotechnology, photonics and chemistry to give polyethylene (plastic wrap). It allows thermal radiation, air and water vapor to pass right through and is opaque to visible light. As an initial step, they created computer models that captured the optical properties of nanoporous polyethylene. Simulations were conducted on a local compute cluster at Stanford, in addition to SDSC’s petascale Comet supercomputer and Stampede at the Texas Advanced Computing Center at the University of Texas in Austin. The resulting models encompassed a wide optical wavelength range, from the visible to infrared.

“By adjusting for a variety of parameters we were able to identify a pore size range, a nanopore, that best suited the purpose of the textile, one that is highly opaque visibly and at the same time highly transparent in the thermal wavelength range,” said Fan. “Solving for electromagnetic wave propagation in large 3D structures is very computationally demanding, and can only be done on high-performance computers,” he added. “Otherwise it would take too much of time. The large shared memory in the Comet cluster was quite beneficial for the code that we were using.”

Using their computer models as a guide, they found a variant of polyethylene commonly used in battery making that has a specific nanostructure that is opaque to visible light yet is transparent to infrared radiation, which could let body heat escape. This provided a base material that was opaque to visible light for the sake of modesty but thermally transparent for purposes of energy efficiency. They modified the polyethylene by treating it with benign chemicals to enable water vapor molecules to evaporate through nanopores in the plastic, allowing the plastic to breathe like a natural fiber.

To make this thin material more fabric-like, they created a three-ply version: 2 sheets of treated polyethylene separated by a cotton mesh for strength and thickness. To test the cooling potential of their three-ply construct versus a cotton fabric of comparable thickness, they placed a small swatch of each material on a surface that was as warm as bare skin and measured how much heat each material trapped. The cotton fabric made the skin surface 3.6 F warmer than their cooling textile. The researchers said this difference means that a person dressed in their new material might feel less inclined to turn on a fan or air conditioner.

The researchers are continuing their work on several fronts, including adding more colors, textures, and cloth-like characteristics to their material. http://ucsdnews.ucsd.edu/pressrelease/a_scientific_advance_for_cool_clothing_temperature_wise_that_is

Recent Comments