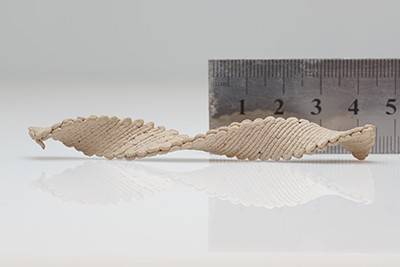

Researchers report that they have developed a new composite material designed to change behaviors depending on temperature in order to perform specific tasks. These materials are poised to be part of the next generation of autonomous robotics that will interact with the environment.

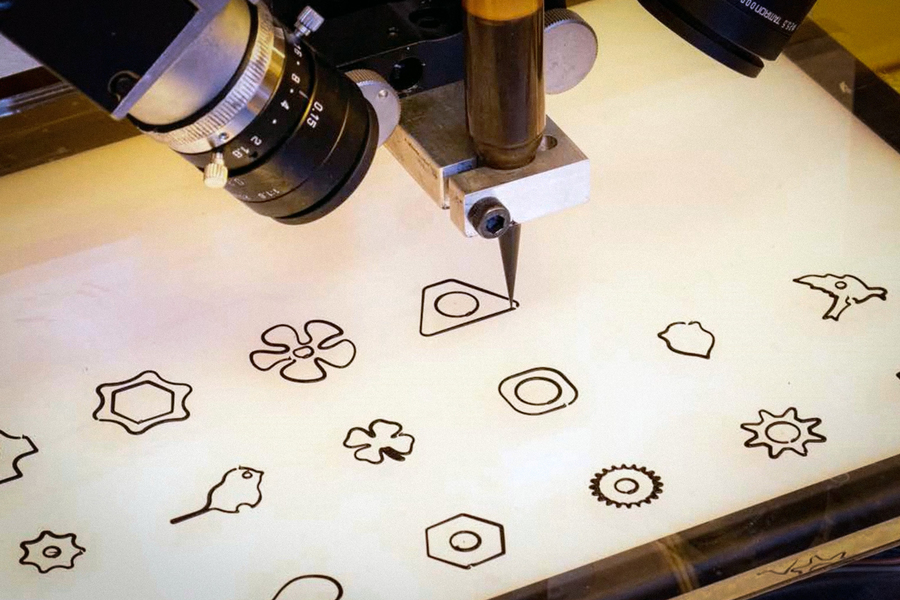

The new study conducted by University of Illinois Urbana-Champaign civil and environmental engineering professor Shelly Zhang and graduate student Weichen Li, in collaboration with professor Tian Chen and graduate student Yue Wang from the University of Houston, uses computer algorith...

Read More

Recent Comments