In the quest to develop life-like materials to replace and repair human body parts, scientists face a formidable challenge: Real tissues are often both strong and stretchable and vary in shape and size.

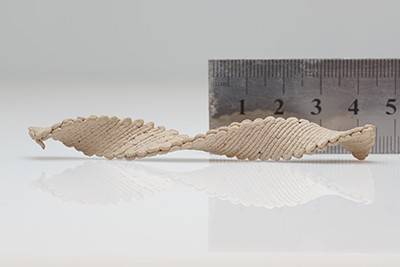

A CU Boulder-led team, in collaboration with researchers at the University of Pennsylvania, has taken a critical step toward cracking that code. They’ve developed a new way to 3D print material that is at once elastic enough to withstand a heart’s persistent beating, tough enough to endure the crushing load placed on joints, and easily shapable to fit a patient’s unique defects.

Better yet, it sticks easily to wet tissue.

Their breakthrough, described in the Aug...

Read More

Recent Comments