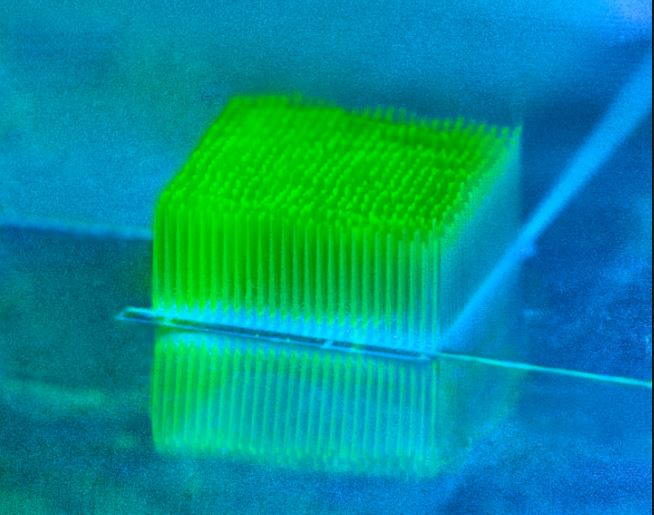

Credits:Image: Courtesy of the researchers

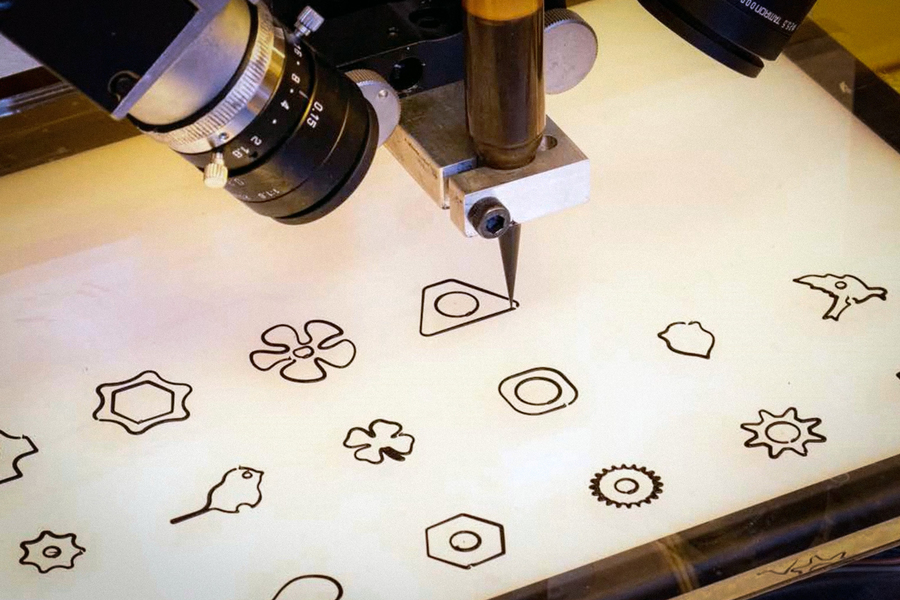

Researchers train a machine-learning model to monitor and adjust the 3D printing process to correct errors in real-time. A new computer vision system watches the 3D printing process and adjusts velocity and printing path to avoid errors. Training the system in simulation, researchers avoid the costly trial-and-error associated with setting 3D printing parameters for new materials.

Scientists and engineers are constantly developing new materials with unique properties that can be used for 3D printing, but figuring out howto print with these materials can be a complex, costly conundrum.

Often, an expert operator must us...

Read More

Recent Comments