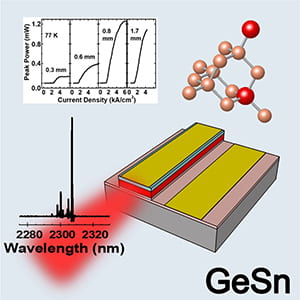

Materials science researchers, led by electrical engineering professor Shui-Qing “Fisher” Yu, have demonstrated the first electrically injected laser made with germanium tin. Used as a semiconducting material for circuits on electronic devices, the diode laser could improve micro-processing speed and efficiency at much lower costs.

In tests, the laser operated in pulsed conditions up to 100 kelvins, or 279 degrees below zero Fahrenheit.

“Our results are a major advance for group-IV-based lasers,” Yu said...

Recent Comments