Engineers have unveiled an encodable multifunctional material that can dynamically tune its shape and mechanical properties in real time. Inspired by the remarkable adaptability observed in biological organisms like the octopus, a breakthrough has been achieved in soft machines. A research team, led by Professor Jiyun Kim in the Department of Materials Science and Engineering at UNIST has successfully developed an encodable multifunctional material that can dynamically tune its shape and mechanical properties in real-time. This groundbreaking metamaterial surpasses the limitations of existing materials, opening up new possibilities for applications in robotics and other fields requiring adaptability.

Current soft machines lack the level of adaptability demonstrated by their biological counterparts, primarily due to limited real-time tunability and restricted reprogrammable space of properties and functionalities.

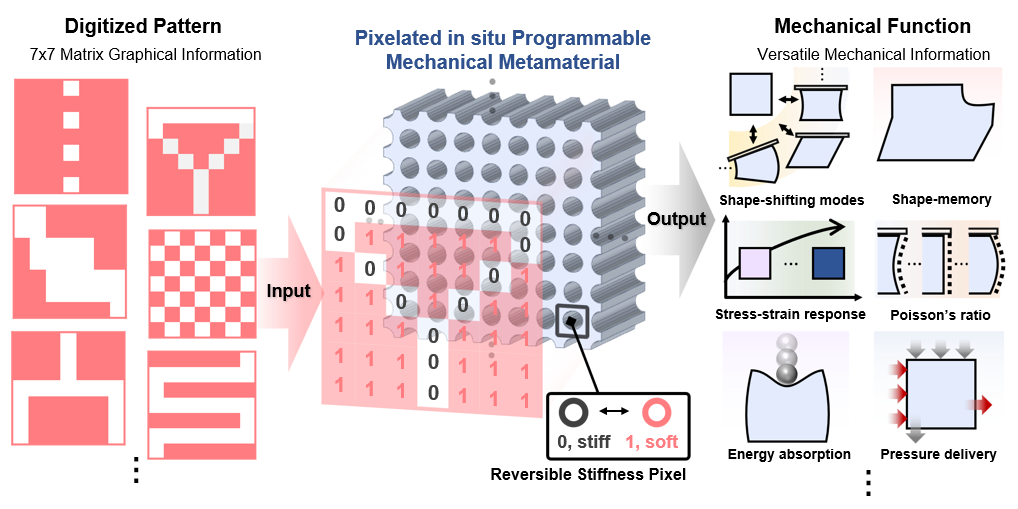

In order to bridge this gap, the research team introduced a novel approach utilizing graphical stiffness patterns.

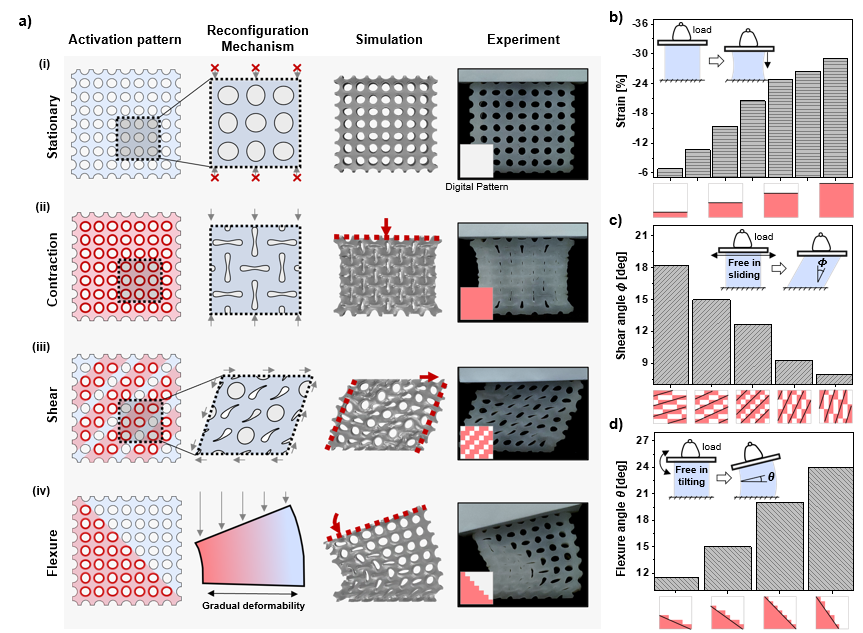

By independently switching the digital binary stiffness states (soft or rigid) of individual constituent units within a simple auxetic structure featuring elliptical voids, the material achieves in situ and gradational tunability across various mechanical qualities.

The digitally programmable material exhibits remarkable mechanical capabilities, including shape-shifting and memory, stress-strain response, and Poisson’s ratio under compressive load.

Furthermore, it demonstrates application-oriented functionalities such as tunable and reusable energy absorption and pressure delivery.

This breakthrough material serves as a stepping stone toward the development of fully adaptive soft robots and smart interactive machines.

“We have developed a metamaterial that can implement desired characteristics within minutes, without the need for additional hardware,” stated Jun Kyu Choe (Combined MS/Ph.D. Program of Materials Science and Engineering, UNIST), the first author of the study.

“This opens up new possibilities for advanced adaptive materials and the future development of adaptive robots.”

The research team showcased the material’s potential by demonstrating an “adaptive shock energy absorbing material,” which adjusts its properties in response to unexpected impacts.

By minimizing the force transmitted to the protected object, this material significantly reduces the risk of damage or injury.

Additionally, the team utilized the metamaterial as a “force transmission material,” capable of delivering forces at desired locations and times.

By inputting specific digital commands, the material selectively operates adjacent LED switches, enabling precise control over force transmission pathways.

Professor Kim emphasized the compatibility of this metamaterial with artificial intelligence technologies, such as deep learning, as well as existing digital technologies and devices.

“This metamaterial, capable of converting digital information into physical information in real-time, will pave the way for innovative new materials that can learn and adapt to their surroundings,” added Professor Kim.

The research, published in the January 2024 issue of Advanced Materials, has been selected as a back cover. The project received support from the National Research Foundation of Korea (NRF), the Ministry of Science and ICT (MSIT), and the Korea Institute of Materials (KIMS). https://news.unist.ac.kr/worlds-first-metamaterial-developed-to-enable-real-time-shape-and-property-control/

Recent Comments